Trenchless rehabilitation of a pipeline

Rehabilitation of a pipeline using a sleeve is a method, in which the resin-impregnated sleeve is placed with a winch into the pipeline section to be rehabilitated, untucked by supplying compressed air and cured with ultraviolet lamps.

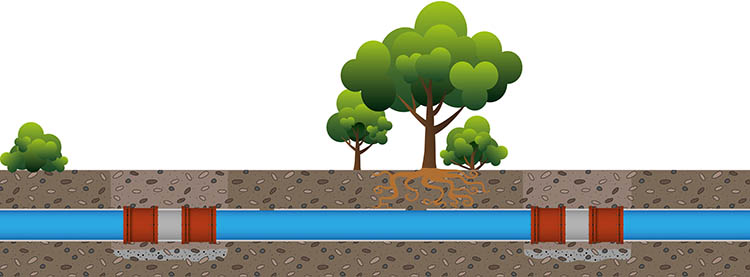

A liner makes it possible to obtain a new strong pipe closely attached to the walls of the collector being repaired and exactly repeating its geometry.

As a rule, four hours are enough to repair the pipeline and to re-commission the repaired section.

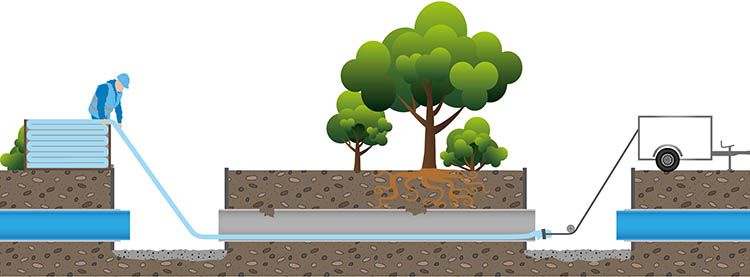

Rehabilitation stages

A protective film is laid into the old pipeline and then a liner is pulled in.

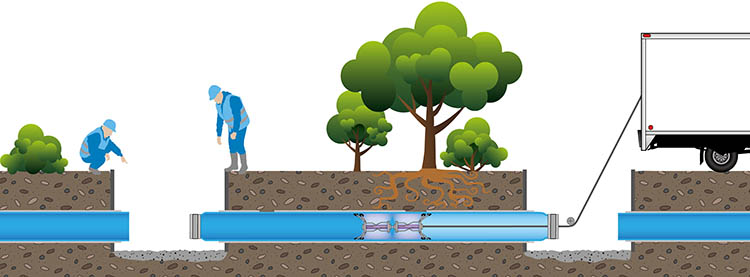

On the edges of the liner special packers are mounted. Through them, compressed air is supplied, which inflates the liner. The liner fits snugly against the walls of the old pipeline, repeating its shape.

Sources of ultraviolet emission move inside the liner at a constant speed, contributing to its curing.

Immediately after curing, the rehabilitated section is being attached to the existing pipeline.

Optimal for the city

Rehabilitation with a polymer sleeve is the most optimal solution for trenchless pipeline repair for urban and municipal services, as well as for design offices. The advantages of such pipeline rehabilitation are obvious in narrow urban and residential areas with traffic.

Residents, drivers and owners of adjacent areas require fast, clean and compact rehabilitation on a small scale and in the shortest possible time. In addition, when performed in open areas, it inflicts only minor and temporary damage.